By coupling Information & Analytics, every manufacturing unit can adeptly oversee and streamline its diverse functions, including the shop floor, supply chain, sales, and post-sales service. This can be achieved by utilizing the available data to drive productivity and profit through data-driven decision-making programs.

Accelerate Data-driven Smart Operations with NRoot Labs Manufacturing Analytics

Our comprehensive self-service data analytics platform empowers organizations to harness operational data at every stage of the data lifecycle, from the shop floor to the top floor. This enables them to maximize value, minimize risk, and leverage the full potential of their data resources.

Improved Efficiency: Operational analytics helps identify inefficiencies and bottlenecks in manufacturing processes, enabling organizations to optimize resource allocation, reduce waste, and improve overall operational efficiency.

Enhanced Quality and Yield: By analyzing operational data, organizations can identify patterns and trends that impact product quality and yield. This allows for proactive measures to be taken, such as identifying and resolving quality issues in real-time, resulting in improved product quality and higher yield rates.

Faster Problem Resolution: Operational analytics enables timely identification and resolution of production issues by providing real-time insights into the manufacturing processes. This helps minimize downtime, improve equipment maintenance, and reduce the time required to resolve problems, thus enhancing overall productivity.

Optimal Inventory Management: Analytics helps organizations gain better visibility into inventory levels, demand patterns, and supply chain performance. This enables improved inventory management, reducing excess inventory and stockouts, optimizing storage space, and minimizing carrying costs.

Data-Driven Decision Making: Operational analytics provides organizations with actionable insights based on data analysis. This empowers decision-makers to make informed decisions regarding production planning, resource allocation, process improvements, and other critical areas, leading to better operational outcomes.

Predictive Maintenance: By analyzing operational data and equipment performance, organizations can implement predictive maintenance strategies. This helps detect equipment failures or maintenance needs in advance, minimizing unplanned downtime, optimizing maintenance schedules, and improving overall equipment reliability.

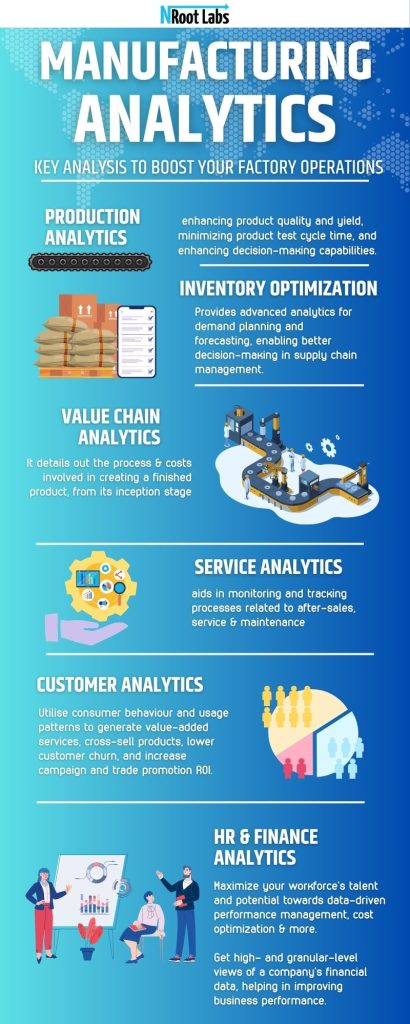

Just like how manufacturing industries convert raw materials into valuable finished products, discover how our solution on some of the key Manufacturing analytics drive our customers to achieving efficiency and value-added insights from their raw data! The below infographic helps explain the various analysis:

NRoot Labs is an end-to-end BI solutions provider transforming Data into Valuable Insights for Manufacturing Industry.